- Marketplace

- Blog

- AI revolutionises sewer surveys

A post by Valentin Kovachev

A post by Valentin Kovachev

Sewerage Asset Analyst

Our partnership with artificial intelligence (AI) company Molfar, which came about through our AI sewer scanning Marketplace challenge, is already revolutionising our sewer survey activity.

Every year Wessex Water conducts CCTV surveys on hundreds of kilometres of sewers. A large number of these are proactive surveys to help us understand the condition of our sewerage network. This feeds into our risk modelling and prioritisation, so that we target the right sewers for investment.

Traditionally staff ‘drive’ a CCTV robotic camera through a sewer, manually controlling the camera and watching footage live to log defects and issues.

For a long time this has been the established method to obtain condition information for gravity sewers. However it is a costly and time-consuming process, and it all happens from a van at the side of the road, which can be disruptive to the local community.

We wanted to know if AI could increase productivity and thereby improve the efficiency of our spend in this area. Could an AI-based algorithm produce a log of observed defects from CCTV footage? Back in 2019, we launched a Marketplace challenge to find out.

The Marketplace challenge

We published historical CCTV footage and gave companies three months to develop their algorithms, which were then assessed against further CCTV footage. As a result, we began an initial trial with four companies in January 2021.

We then completed a further trial period, testing three companies’ products in a more live business as usual environment. This gave us greater insight into how the products work day to day, both in terms of accuracy and usability.

Our partnership with Molfar

Following the successful trial, in April 2023 we began a contract with Molfar, an AI research and development firm with expertise in deep machine learning models and software development.

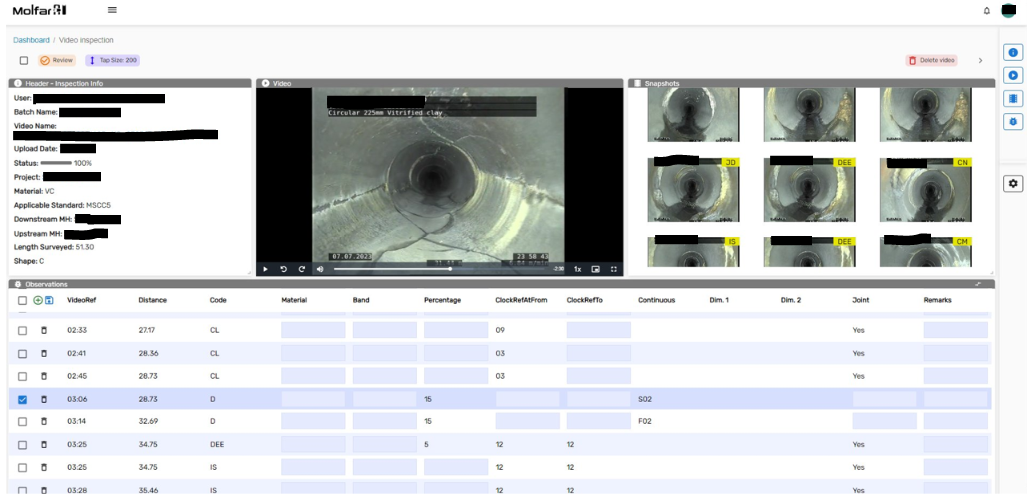

Since then we have been using their tool for the majority of the CCTV surveys in our proactive condition survey programme – over 100km so far. We simply ‘drive’ the robotic camera straight through the sewer, then Molfar’s AI-based algorithm produces a log of observed defects from the video footage.

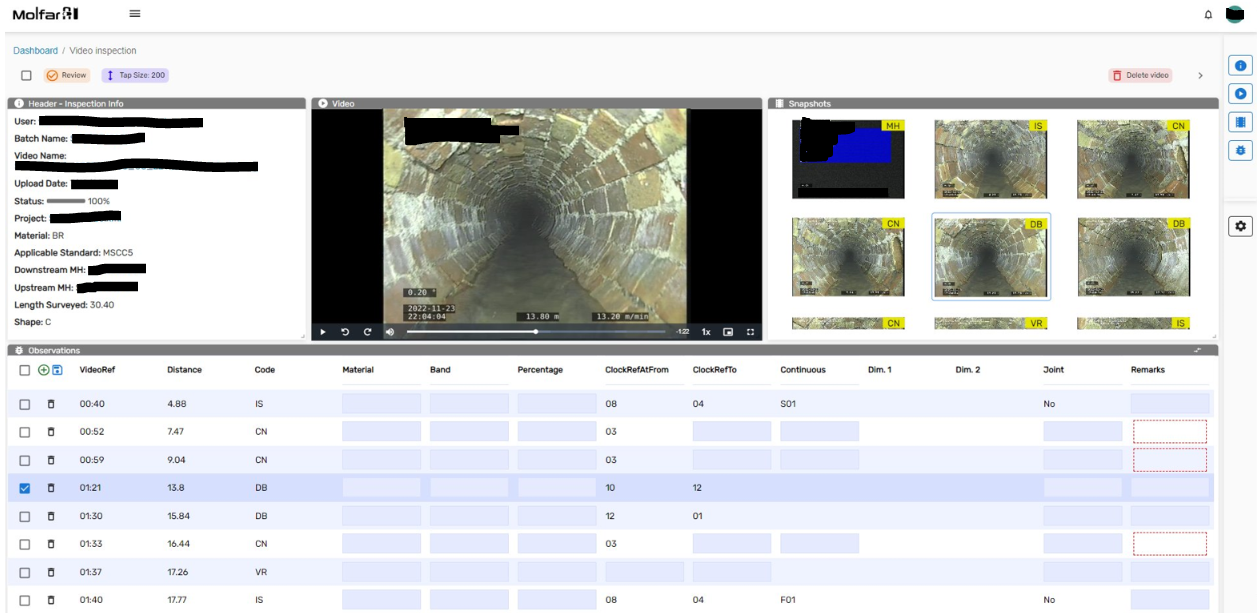

Molfar system screenshot - displaced bricks

So there’s no need for our crew to watch the footage live and log defects themselves, as they would have done traditionally. Only in rare cases do we need to do a further survey by the ‘traditional’ approach – for example, to investigate a specific fault in greater detail.

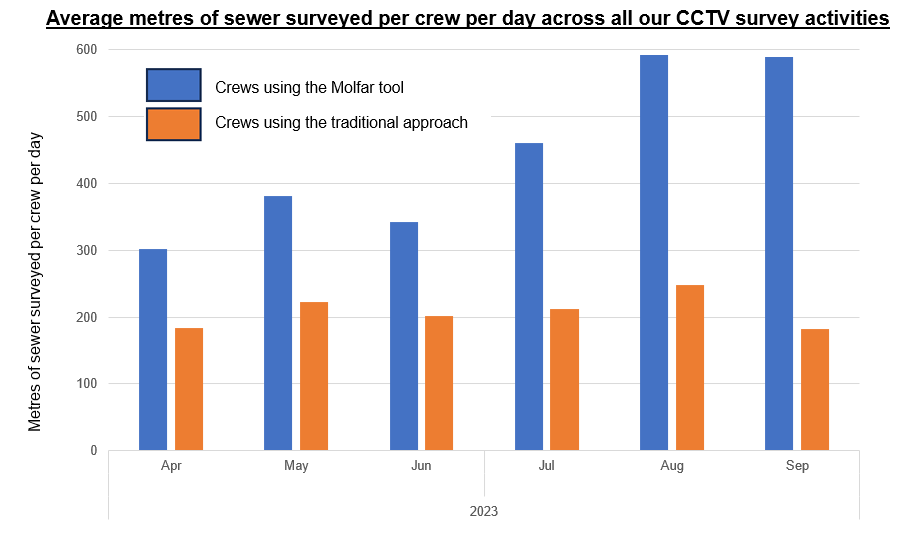

This approach uses crew time more efficiently. The graph below shows the average metres of sewer surveyed per crew per day across all our CCTV survey activities, with the blue bars representing crews using the Molfar tool and the orange bar showing crews using the traditional approach. The tool has more than doubled crew productivity on average and in later months it has tripled.

![]()

This increased productivity has enabled us to significantly expand our proactive survey programme, so we are now surveying additional lengths for the same total cost. Apart from the obvious cost savings there are multiple other benefits. By surveying more sewers each year, we’re more likely to spot a potential issue as it is developing. We can then intervene, for example with cost-effective “no-dig” renovation, before an incident occurs. This is much better for customers and the environment. Furthermore, collecting asset information at a greater pace provides a better evidence base for prioritising our future investment.

So what’s next? We are collaborating with other areas of the business to adopt the tool across all of our inspection programmes, such as pollution and infiltration investigations.

Our partnership with Molfar is clearly a real success for our sewerage and CCTV teams, but it’s also a great example of our Marketplace approach.

By sharing the challenge with the wider market as an open question, and sharing relevant data alongside, we were able to draw on expertise from outside the industry and thoroughly test products to ensure we chose the right solution.

Molfar system screenshot - sewer deformation